Nickel Balls

Spray welding of nickel alloys to repair cast iron blow moulds, blank moulds and bottom plates can cause gas to be formed and trapped in the weld, only to be exposed during the last stage of turning or polishing as surface pin holes. These pin holes are undesired as it will result in defects on the glass containers being produced, causing production losses and customer complaints.

Traditional spray welding of the cast iron tooling to close pin and vent holes is not cost or time effective. Redfoot supplies a solution to this problem by providing a spot welder and nickel alloy balls, making repairs possible in seconds.

Repairing of the pin holes are done in a quick and effective manner by using a spot welder and nickel alloy balls of sizes 1mm – 2.5mm. The correct size nickel alloy ball is placed in the pin hole, the spot welder electrode is pressed against the ball and the weld is performed in milliseconds. The welded area surface is polished and the repair is complete.

-

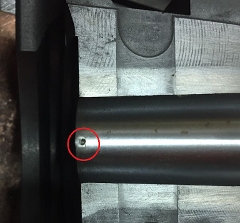

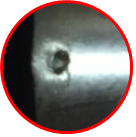

Mould With Pin Hole

-

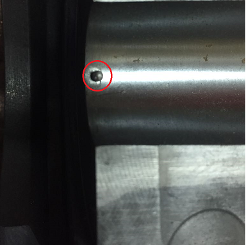

Insert Ball

-

Perform Spot Weld

-

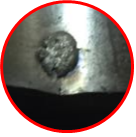

After Spot Weld

-

Perform Polishing

-

Completed Repair