Mould Maintenance

Redfoot has a complete range of products to assist in mould equipment maintenance. Using the correct equipment and consumables is a critical part in extending the life of mould equipment resulting in more containers produced on a mould set which translates into lower cost per unit produced.

ZIRPROCeramic blasting media

Zirpro supplies a range of ceramic beads for rotary blasters. Bead usage is 10x less than conventional glass or steel shot with an estimated 5x improvement in mould life. The ability to withstand bead breakage ensures that impact indentations on the mould equipment is kept to a minimum, producing a smoother finish with less wear on the mould equipment.

Coated Abrasives

Redfoot supplies a range of coated abrasives especially engineered to service the glass container market. The sandpaper backing has a higher flexability when compared to standard products on the market. This results in the abrasive media conforming to the shape of the mould equipment producing a more even material removal across the face of the mould/blank. Flexability reduces the risk of surface indentations and the mould equipment being rejected on inspection. All abbrasives can be supplied as standard flex, high flex or medium flex in the full grid range.

The range of coated abrasives are:

- Spiral bands in various lengths and diameters

- Flapper wheels in various thicknesses and diameters

- Sandpaper with glued backing for mould/blank facing

- Polishing points – rubber impregnated abrasive media

- Range of Nylon polishing wheels

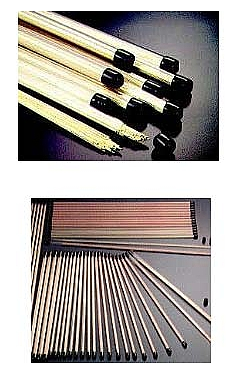

Spark Drilling (EDM)

Cleaning of vacuum holes in the moulds is critical to ensure the container is formed with no air trapped in between the mould and the glass. Blockage of the vacuum holes occur during normal operation, during cleaning and during weld repairs of the moulds. EDM tubes are used extensively in the cleaning of these vacuum holes in diameters ranging from 0.3-0.5mm.

Redfoot supply:

- EDM tubes – brass or copper

- Ceramic guides in lengths of 30mm, 50mm, 75mm and 100mm

- Water seals (Grommits)

Air/Water Blast Cabinets

Cleaning carbon off from critical areas have always been a balance between removal of the virgin material and having a dirt free surface to work with.

Critical areas such as stippling, embossing, threads and edges have always born the brunt of this balance, resulting in excessive repair work that needed to be done after cleaning.

Using the wetblast cabinet, glass bead impact is reduced with the water acting as a flushing and cushioning agent, resulting in a clean surface with no virgin material taken away on the critical areas.

- Abrasive media usage is much less when compared to a normal airblast cabinet

- Extraction of the dust is not necessary as dust is suppressed by the water vapour

- Cabinett and associated equipment is made with stainless steel to ensure long lifetime

- Additives to the water prevent oxidation of the mould equipment

- Removal of only the carbon allows for better inspection on mould equipment

- Longer life on mould equipment