Graphite Consumables

Mersen

Mersen supplies a complete range of graphite consumable parts to facilitate the removal of hot glass containers from the I.S. machine and to transport thehot glass containers to the lehr under the Cerberite range of products. Special graphite grades for exact applications are specified to ensure longer and shorter production runs are catered for. Redfoot with it’s experience in the glass container industry, is perfectly positioned to assist customers with graphite product modifications and/or grade specifications to ensure that plant specific problems are solved, creating value for the end user in productivity and efficiency.

Gob Forming and Delivery

- Rotating tube graphiteliner – lubrication, ball bearing free liners to ensure a long and trouble free tube rotation operation

- Loading tubes – Graphite loading tubes are manufactured according to customer’s drawings.

- No cooling is required and use of the correct graphite grade allows for a long lifetime with exact loading into the scoop.

- Gob reject/Flipper pads - Standard machine manufacturer and custom sizes are supplied to ensure gob’s are guided into the reject chute.

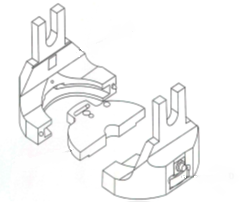

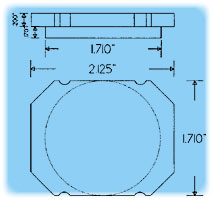

Take out inserts

All custom finishes and GPI specifications (Glass Packaging Institute) can be supplied. Inserts can be supplied to fit existing holders from any OEM in any style or configuration. Mersen also supply the insert holders in various styles and configurations to ensure a comprehensive and full service is given to the end user. Various graphite ranges are available that will cater for short, medium and longer runs – all materials are glass grade specified to ensure a high resistance to glass checking and low wear, ensuring a higher plant productivity and efficiency.

Warehandling

Warehandling products can be broken into two main catagories, namely machined parts and moulded parts. These insulating parts are situated on the wiper/pushers, radial transfer/starwheel fingers and guides, and the stacker pockets as inserts or complete pockets.

Machined parts - any shape or size to replace existing insulating materials can be machined which will ensure direct replacement and long service life.

Moulded parts – standard shapes and sizes for fingers and backplates can be supplied to fit OEM equipment as a direct replacement.

Machined parts - any shape or size to replace existing insulating materials can be machined which will ensure direct replacement and long service life.

Moulded parts – standard shapes and sizes for fingers and backplates can be supplied to fit OEM equipment as a direct replacement.