I.S. Machines

BDF Industries

Ranks among the four largest suppliers of engineering solutions and equipment to the glass industry worldwide. It is the sole player in the hollow glass market able to offer turnkey plants from the engineering to maintenance services. BDF Industries is an EPC company of plants and equipment, from food &ules; beverage to perfumery and pharmaceutical products. BDF Industriesoperates through four product lines focused on different activities within the glass industry:

Forming

BDF Industries glass container forming product line is the historical core business. BDF Industries is able to provide a wide range of machineries with a high level of production flexibility to meet the customers’ requirements.

With more than 65 years’ experience in glass forming field, BDF Industries can offer the complete range of IS machine including gob forming and delivery, ware handling, container and variable equipment. The glass forming machineries are fully designed and assembled in house by BDF Industries in Italy, which has relevant knowledge of production process of the most important glass manufacturers in the world (e.g. strong credentials for forming business in O-I, Saverglass, Sisecam, Vetropack, Vitro…)

Our R&D office is focused to find the best solutions applied into IS machines in order to match lower production costs for our Customers thanks to higher reliability and maintainability of our product. We continue to work towards research and innovations that will deliver genuine advantages in productivity and efficiency for our customers glass factories located in different areas around the world.

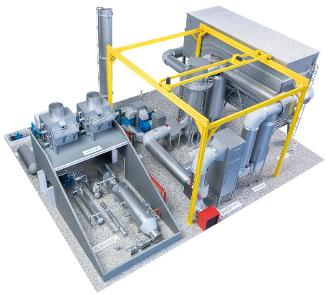

Melting

BDF industries Melting product line includes the complete glass melting and conditioning technologies for design and supply of furnaces, working end &forehearths. The range of products includes also the relevant equipment like oil and gas burners and firing system, air and exhaust reverse valve, batch chargers, forehearth glass mixers etc.

BDF Industries furnaces are engineered by high level of customization with focus on energy efficiency and the attention to environmental impacts.

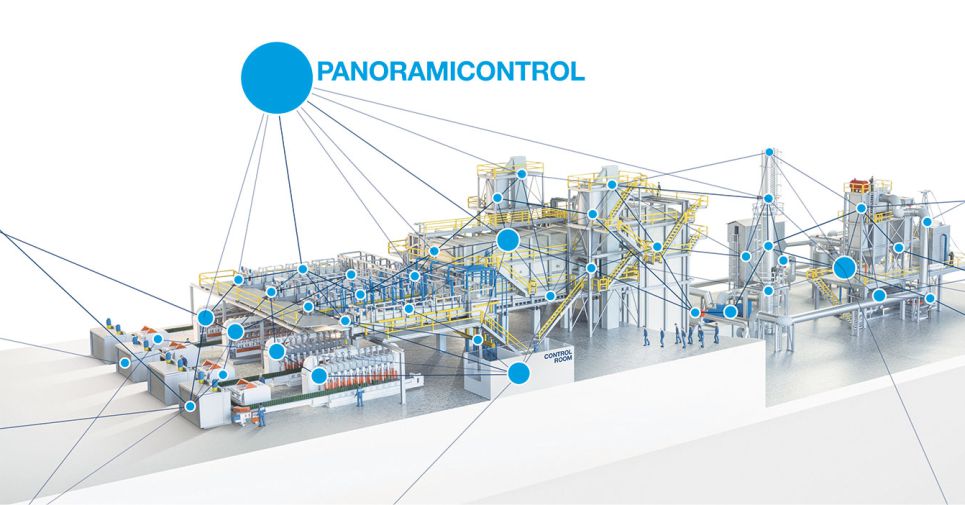

Automation

The automation team involved in the Glass Industry focus its activity on the engineering process and software, during reconditioning and retrofitting of all part of Glass Factory including: plant designing, installation and start-up, network configuration, control, staff training, customer service and remote assistance.

The experienced, qualified, passionate and customer-focused staff is there to add value for customers, partners and suppliers. As part of its own philosophy, the team believes and operates in the sustainable development: the application of its carefully designed and implemented systems greatly save energy and relevant impact on the environment, thus improving the quality of life and the safety of the operators in the field as well as adding economic and social value to the community.

A fundamental key of success in the automatic control is the interlink with melting and forming teams which makes the final product completely fit with the Glass Factory requirements.

Energy

BDF’s experience in the glass industry and automation makes us the best qualified partner when it comes to improve, re-engineer or reinvent a glass production plant or process. To master the challenges of global competition, our customers must minimize costs, continually increase the productivity of their systems and meet ever-stricter environmental regulations. Our innovative and eco friendly solutions help to conserve natural resources, improve energy and capital utilization and optimize processes. For our customers, this means lower raw materials consumption, fewer emissions, greater energy efficiency, lower costs and increased output. BDF supplies the complete package for energy recovery through heat exchangers and have the experience to design and install equipment to treat flue gasses to comply to environmental legislation.

Glass melting and forming is a very sensitive process and it is critical to have a partner that understands downstream and upstream impacts before equipment is introduced. BDF understands glass and is therefore perfectly positioned to understand the impact of equipment on the glass melting process – and this makes them the ideal partner to introduce their own equipment and expertise into your plant.